Our Location

304 North Cardinal St.

Dorchester Center, MA 02124

The new 3D-printer control board (Recore) that was started in 2019 is now mature and ready to start shipping to customers. We are now at revision A5, but the A4 was also working fine, it was just a few minor tweaks related to testability mostly.

But this blog post and accompanying video will be centered around porting Klipper to be compatible with the new Recore. Here is the video, the rest of this post we give some details that did not make it into the video.

Here is that block diagram of Allwinner A64 again for reference.

Normally a Single Board Computer (SBC) that runs Linux is not suited for real time operations. That is why a microcontroller is needed which is why you end up with a combination of regular 3D-printer control board and a Rasberry Pi. There are exceptions, for instance the BeagleBone family has a separate (Programmable Realtime Unit) PRU which solves this elegantly.

In Recore I wanted to get rid of that separate microcontroller and find a solution similar to what the PRUs on the BeagleBone is doing. The solution is to use the AR100 which is a bit of a quirky “microprocessor” embedded on the Allwinner A64. But it’s fast! It can run at 300 MHz. Finding a similar microcontroller as a separate device would increase the final price quite a bit without really adding anything.

As mentioned in the video, in order to use the AR100 for real time operations, and to make it work with Klipper, there were three problems that needed to be solved.

If you try to toggle pins from Linux, you will be disappointed. It is very slow and unpredictable since the pin toggling events are handled by the kernel and the program is running in user space. Also, the event be handled only when the kernel sees fit which can take a while. But even if you set aside a separate core out of those 4 cores in the A64, you would still be hunted by some amount of unpredictability since the toggling even has to be propagated on the same AHB as most other media on the SoC.

By offloading those events to the AR100, we can get very good speed and predictability. The more we can stay away from the AHB dedicated to the AR100, the less jitter we experience on the toggling of those pins. More jitter will cause steps on the stepper motors to appear uneven and can in turn cause wobbling on the finish of printed objects. I’ve not done extensive testing on this, but it would be a very interesting experiment.

The experiment shown in the video shows the difference between toggling pins that are in one of the GPIO banks and comparing to pins that are in the R_GPIO bank. If you look at the chart above, the “path” taken for the AR100 to toggle the pins in the GPIO bank is a bit more crooked and running through two shared buses, one of which potentially has a lot of traffic.

In an effort to offload as much traffic as possible on the AHB, I chose a somewhat unconventional way to set up communication between the main Klipper program running on Linux and the real time bit running on the AR100. The conventional way might be to use a shared memory area to “send” commands, since both CPUs are on the same die. Instead, I chose a loopback between a UART controlled by the A53 cores and an R_UART controlled by the AR100. I’m not burning any bridges here, the shared mem solution is still available in case anyone wants to try it and look at possible benefits and downsides, but now we have to option to do both.

The third and final hurdle was getting a hold of a decent timer for the AR100. There is actually a timer peripheral (R_TIMER) in the A64 dedicated to the AR100, but unfortunately it is not timed by the AR100 CPU clock at 300 MHz. Instead, it is timed by the main oscillator at 24 MHz. This meas that the timer does not have enough resolution to cause stepping in the exact moment needed. But there is another solution, a tick timer facility in the OR1000 ISA . In Klipper, the implementation becomes very simple and even though the program will have to keep polling to check if time matches, the CPU is mostly idle regardless, so it should not make a difference.

Even though Recore now runs, the work on this started about a year ago, so the branch of Klipper that is was based upon is very outdated. Once Recore A5 is available in the shop, work will shift back to upstreaming the AR100 patches in Klipper so the work will be maintained. But at lest there is a way to print with the Recore boards, and that is a good starting point.

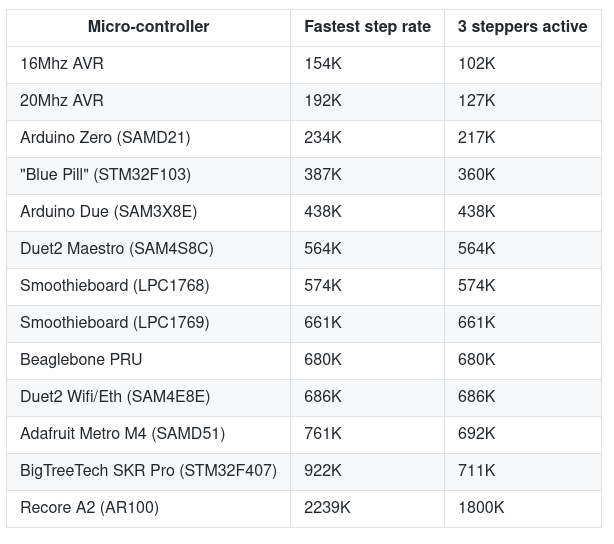

Like I mentioned in the videos, it looks like the AR100 is doing very well in terms of print speed compared to other solutions measured by Klipper.

[…] you’d like to learn more about Elias’ work on AR100 core, check out his recent blog post where he explains how he used the real-time core to toggle the pins much faster and predictably […]

[…] о работе Элиаса над ядром AR100, ознакомьтесь с его недавним постом в блоге, где он объясняет, как он использовал ядро реального […]

[…] más información sobre el trabajo de Elias en el núcleo AR100, consulte su publicación de blog reciente donde explica cómo usó el núcleo en tiempo real para alternar los pines de […]

[…] de las impresoras 3D, [Elias Bakken] desde el [Intelligent Agent] Workshop ha lanzado un nuevo placa controladora llamada Recore. La impresora 3D típica tiene un controlador dedicado que maneja aspectos en tiempo real de la […]

[…] the world of 3D printers, [Elias Bakken] from the [Intelligent Agent] workshop has released a new controller board called Recore. The typical 3D printer has a dedicated controller which handles the real-time aspects of driving […]

[…] 如果你想了解更多关于 Elias 在 AR100 内核上的工作,请查看他近期的博客文章,其中有他解释如何使用实时内核比使用Linux更快、更可预测地切换管脚,在Cortex-A53 内核和AR100之间设置UART通信以及设置计时器的挑战等内容。如果你更喜欢视频格式的解释,请观看下面的视频。 […]